RISK MITIGATION IN UNDERGROUND CONSTRUCTIONS VIA NUMERICAL ANALYSIS

Introduction

Underground constructions are used worldwide for urban development such as subway systems, basements for high-rise buildings, and underground carparks and shopping centres. However, the construction process will inevitably induce ground movement and impose risks to adjacent structures and facilities. Strict regulations, therefore, are imposed on allowable ground deformations during the construction phase. Necessary safety measures are also needed to mitigate these risks.

As a very complex soil-structure interaction problem, the performance of underground constructions is influenced by the sophisticated soil behavior, complex retaining structures, and variable construction sequences. Finite element analysis is an effective tool to study its mechanism, and has been routinely used in design and research in the underground constructions. It provides the necessary information for design purpose; it can also be used to predict the behavior of underground constructions.

Case studies

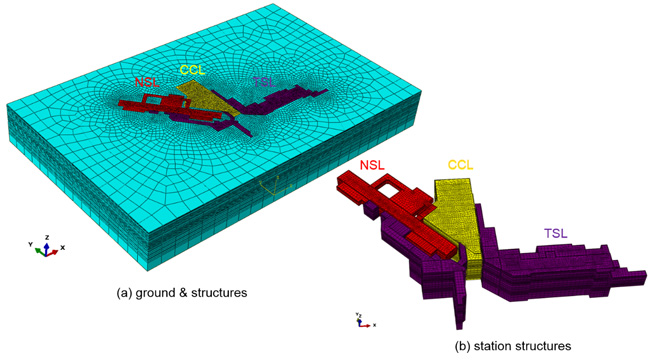

Fig. 1 shows one current project of the author, the underground construction for a new MRT station next to two existing MRT stations in Singapore. To understand the influence of the construction to the existing stations, a complex finite element model was built in Abaqus 6.14 to predict the performance of the ground and structures during the construction, based on information from design and site investigation. Calibration with the field measurement is in progress to improve the accuracy of the analysis.

This project is built upon previous experience of the author during his PhD work at University of Oxford (Dong, 2014), in which he addressed a number of issues in the analysis of deep excavations through comprehensive case studies.

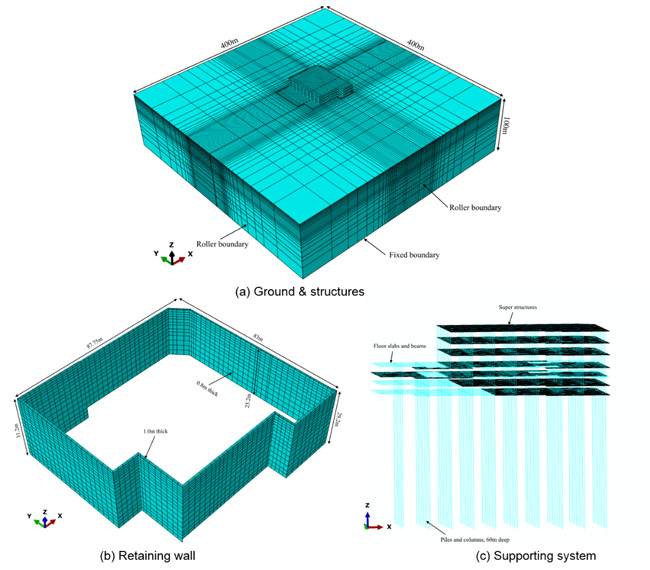

Fig. 2 shows one of these case studies, the basement construction for a high-rise building in Shanghai. This model, built in Abaqus 6.11, included geotechnical and structural details such as the ground, retaining wall, support system, and construction sequence. Comparison with the measured data and discussion on several modelling procedures can be seen in Dong, Burd & Houlsby (2016).

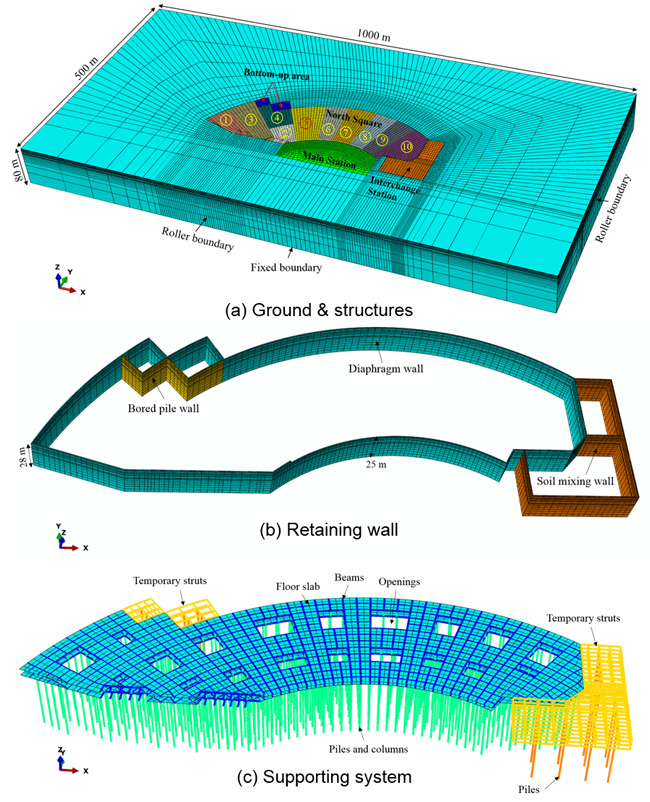

Fig. 3 shows another case study, the constrution for a underground shopping centre in Shanghai. This case study extended the experience of the previous basement excavation to a more complex one, and addressed some issues related to construction processes. Results and discussion of this case study can be referred to Dong, Burd & Houlsby (2015).

Conclusions

Finite element analysis is effective in the study of underground constructions. It can capture the observed performance of the underground constructions satisfactorily. However, the analysis is also challenging, and various issues in the modelling procedures need careful attention.

References

Dong, Y. (2014) Advanced Finite Element Analysis of Deep Excavation Case Histories. DPhil thesis, University of Oxford, Oxford, UK.

Dong, Y., Burd, H.J. & Houlsby, G.T. (2016) Finite element analysis of a deep excavation case history. Géotechnique. 66 (1), 1–15.

Dong, Y., Burd, H.J. & Houlsby, G.T. (2015) Finite element study of deep excavation construction processes. Géotechnique. (under review).